Bugatti is expanding its use of 3D printing in its latest hypercar.

Bugatti uses 3D printing to produce components for what the company calls "one-off" low-volume models.

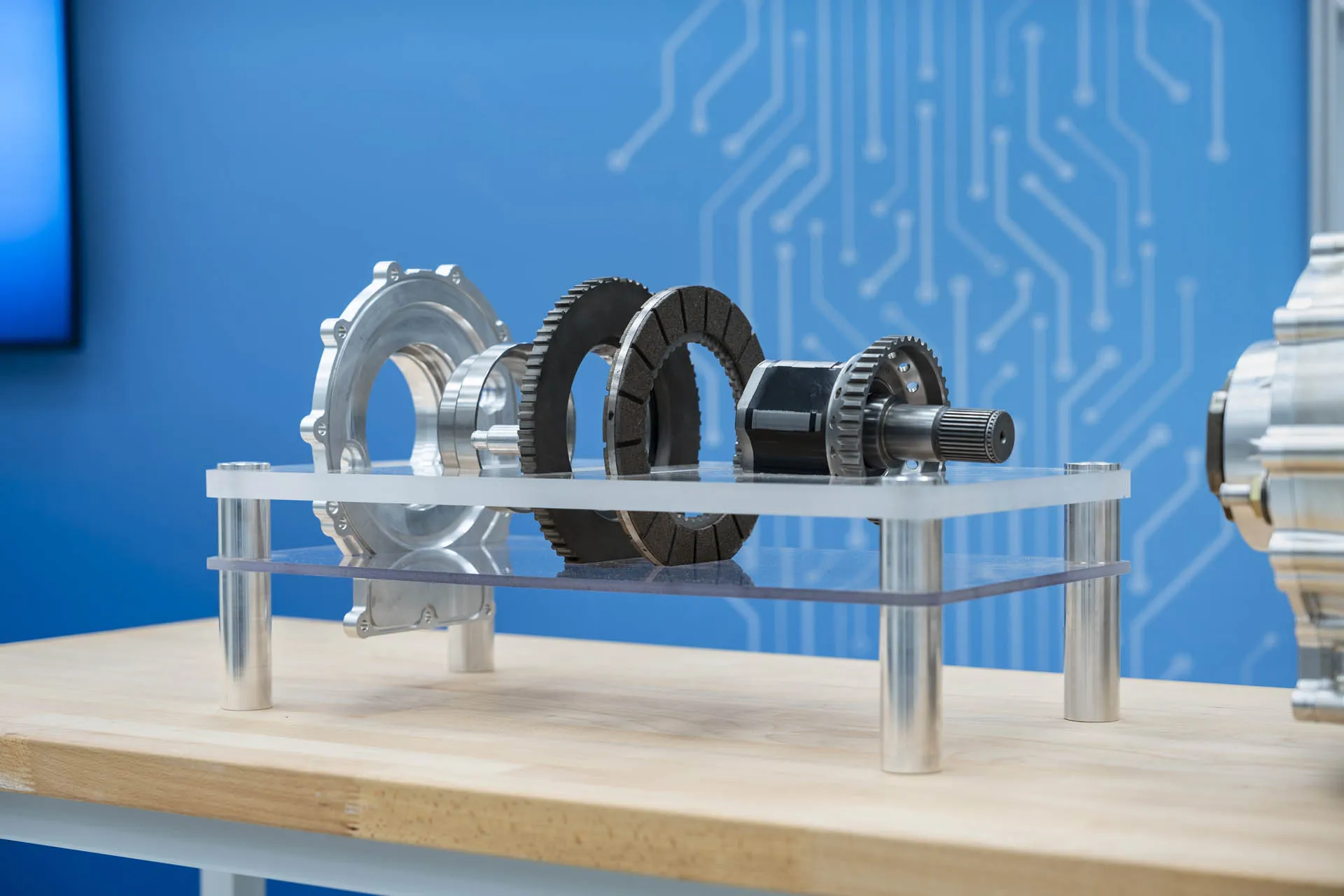

Bugatti first tested the technology a few years ago by making 3D printed titanium brake calipers. These calipers were 40% lighter than conventional cast aluminum calipers and could withstand temperatures up to 2,000 degrees Fahrenheit.

Now Bugatti is expanding the use of 3D printing to other components for its hypercars. On Wednesday, Bugatti announced that it will 3D print heat shields for the exhaust systems of its recently introduced low-production Hirons such as the Sport, Super Sport 300+ and Pur Sport, as well as one-off cars such as La Voiture Noire, Divo and Centodieci.

The company also announced that it will 3D print heat shields for the exhaust systems of cars such as La Voiture Noire, Divo and Centodieci.

Each is unique, and like brake calipers, the new exhaust heat shields offer advantages in mass and strength. For example, the Shillon Supersport 300+ heat shield measures 19" wide, 8.7" long, 5.0" high, is made of titanium, and weighs only 4.0 lbs. which is about 2.6 lbs. lighter than a regular Shillon.

This is achieved by forming hollow sections and changing the thickness of the titanium to only 0.4 mm. The components of the plant consist of four 400 W lasers that work to fuse titanium powder in about 4200 layers. Niels Weimann, Bugatti's head of body development, says: "The minimum material thickness in the multilayer sections is achieved by a so-called lattice structure, where the cavities are filled with numerous filigree struts"

.

Nevertheless, the component can withstand high temperatures up to 1200°C. The high temperature resistance is due to the fact that the part closer to the exhaust pipe is thicker for insulation.

Some automakers in the hypercar sector have taken 3D printing to a more extreme level: the American company Czinger, which uses 3D printing for almost all metal parts on board the 21C car.